Lafont makes extensive use of intimate blends, i.e. blends made at fibre level: Polyester-Cotton (PC) and Cotton-Polyester (CP). Before choosing a model, carefully analyse your expectations in terms of fabrics and how the wearer will use the garments.

Plant-based: cotton, hemp, linen, jute, etc.

Of animal origin: silk, wool, mohair, cashmere…

Of mineral origin: glass fibres, asbestos, etc.

These are chemically created fibres, derived from petroleum products or the result of organic synthesis polyamide, polyester, aramid, acrylic, elastane…

These fibres have a natural base but are chemically treated with cellulose or cellulose derivatives such as acetate, viscose, modal, lyocell, etc.

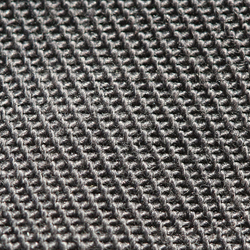

The weave is the way in which the warp threads (vertical threads, parallel to the direction in which the fabric moves during manufacture) are crossed with the weft threads (horizontal threads, perpendicular to the warp).

Privacy policy – Terms and conditions – Legal information – Privacy & Cookies Policy – Lafont, a Cepovett Group brand

Lafont may use cookies to ensure the proper functioning of the site, to measure performance, to compile statistics and analyses relating to traffic and browsing, and to personalize content. Privacy Policy

Preferences Accept| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". | |

| cookielawinfo-checkbox-functional | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". | |

| cookielawinfo-checkbox-necessary | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". | |

| cookielawinfo-checkbox-others | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. | |

| cookielawinfo-checkbox-performance | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". | |

| viewed_cookie_policy | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-autre | 1 year | CookieYes set this cookie to store the user consent for the cookies in the category "Analytics". |

Until 27 November.

Discover our selection of products at unbeatable prices.

Up to 45% off

Newsletter subscription

Subscribe to our Lafont newsletter, which contains our latest news and the best tips for your workwear.